Technology & Safety Machine Upgrades

The right parts and equipment to keep your butt welder performing like new without the expense of new equipment.

Improve Precision and Productivity with Technology & Safety Butt Welder Upgrades

Upgrade your Micro Weld butt welders with world-class safety & technology. You’ll get the same quality, rugged welders with the safety features you need, creating uniformity with every machine and consistency with every training.

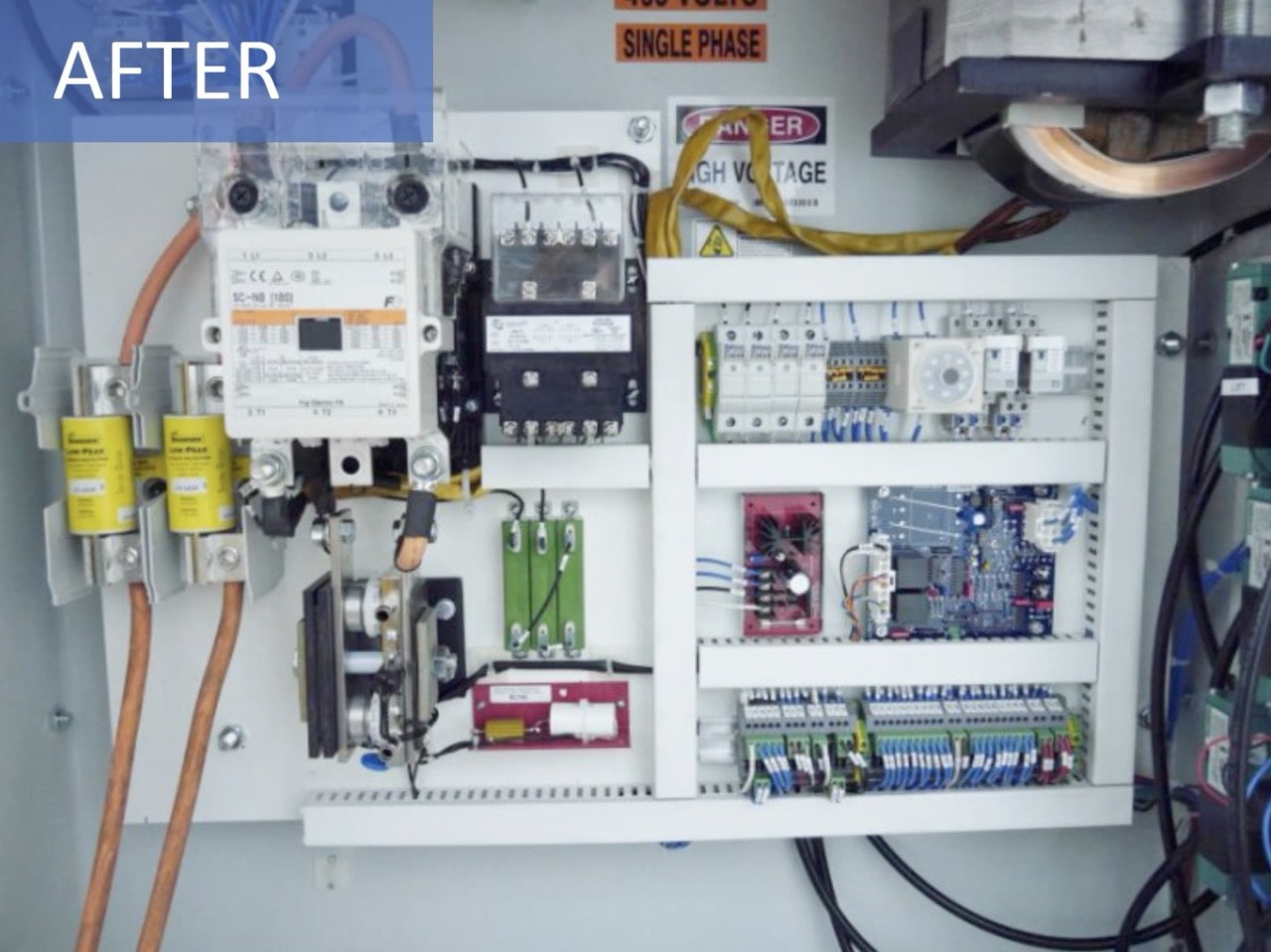

Micro Weld Internal Safety & Technology Upgrades

- New finger-safe covers & components

- Robust, fixed guarding & interlocked movable guarding

- Interlock switch on rear door access panel

- Solid-state heat control

- Inherently safe 24V control circuit

- Electric foot pedals

- Fixed flow control devices

- Emergency stop button / main contractor

- Rotary switch on head guard

- Comprehensive preventative maintenance / repair

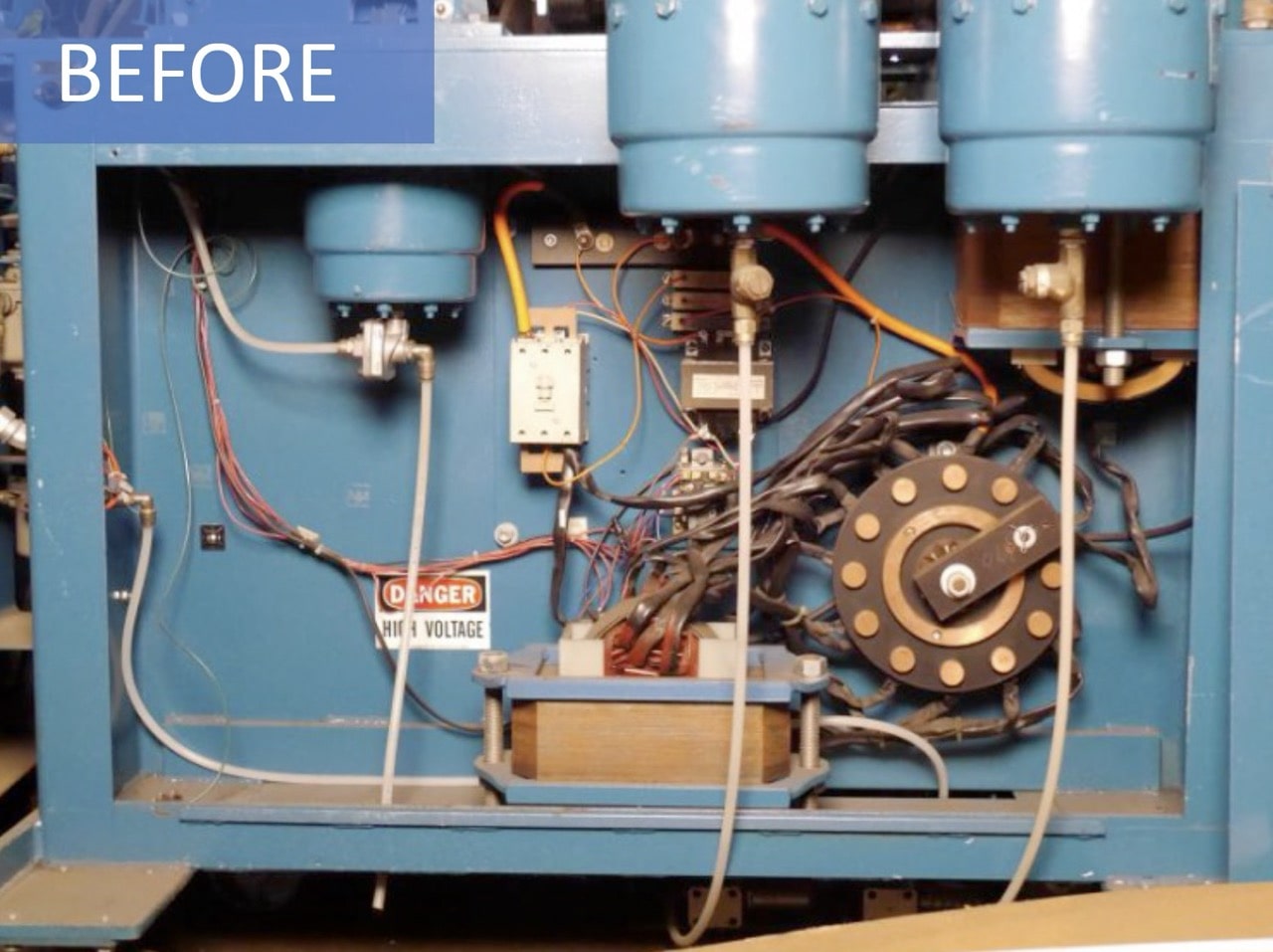

Poorly Altered Equipment Costs You More Than it Saves

As equipment ages, the temptation to opt for quick fixes to keep the production line running smoothly can be strong. While these temporary repairs may appear cost-effective at first, they can compromise safety, lead to more expensive repairs down the line, and potentially necessitate a full replacement sooner than anticipated. Investing in regular maintenance and timely upgrades is a more economical strategy in the long run, ensuring both safety and operational efficiency.

Benefits of Company-Wide Machine Upgrades:

From plant to plant, line to line…

Elimination of operator pinch hazards

Consistent performance and repeatability

Same operator interface

Identical process settings across all lines

Same features and function

Same components for a given model

Simplified training

Welders You Can Count On

It takes more than buying a butt welder to keep your line moving and your employees safe. At Micro Weld, we’re committed to helping you succeed, providing you with the necessary equipment and resources beyond purchasing your welder.

Training

If you have new welding equipment, upgraded equipment, or expand your welding team, ongoing training keeps your employees safe and your butt welder working. Virtual or in-person, we create a training program that fits your needs and your schedule.

Maintenance & Repair

Repairing equipment yourself can cost you more than you save. In-person or virtually, we can help your team with maintenance and repairs, so your equipment works correctly, extending the life of your machine.

In-Plant Installation

You’ve bought the butt welder. Now what? We can help you customize your equipment settings and provide the upfront training for your team so you can get welding.

Replacement Parts

Patching equipment with random parts found in your facility can compromise the machine and increase safety concerns. We provide replacement parts for your butt welder and the support to install it correctly so your equipment is repaired right the first time.

What Our Clients Are Saying

Recently, Adam Fore came to the Okonite Orangeburg South Carolina plant to help us PM several welders and to provide a review and critique of our welding practices. Adam is a very competent and knowledgeable welding expert. Adam guided us through the PM process, and we got several welders back in tip-top shape. He was generally pleased with how we were setting up our welders, which was a relief. He also provided some additional very helpful pointers and recommendations, some of which we have implemented and some we are planning to implement. Adam’s visit was well worth the money. We hope Micro Weld is planning to hire and train one or two more competent and professional technicians, trained by Adam, to take the reins when he retires!

Mike St Jean | Process Engineer at The Okonite Company

You Deserve The Right Equipment To Keep Your Business Moving

Your business relies on solid welds with reliable equipment so you can keep things moving. To do that, you need more than a butt welder. You need the right team to support your business so you can get the job done.

We understand the importance of having the right butt welding equipment, with the support your employees need, so they are safe, and your line keeps moving. When equipment is outdated, altered to make it work, or you need more equipment to expand, you want to know you’re getting what you need without the headache and hassle of figuring it out on your own.

For nearly 100 years, Micro Weld has worked with manufacturers to ensure they get the right equipment with training and support.

You’re welding equipment can make or break your bottom line. At Micro Weld, we provide the support and equipment you need to get the job done, so you can focus on keeping the line moving.