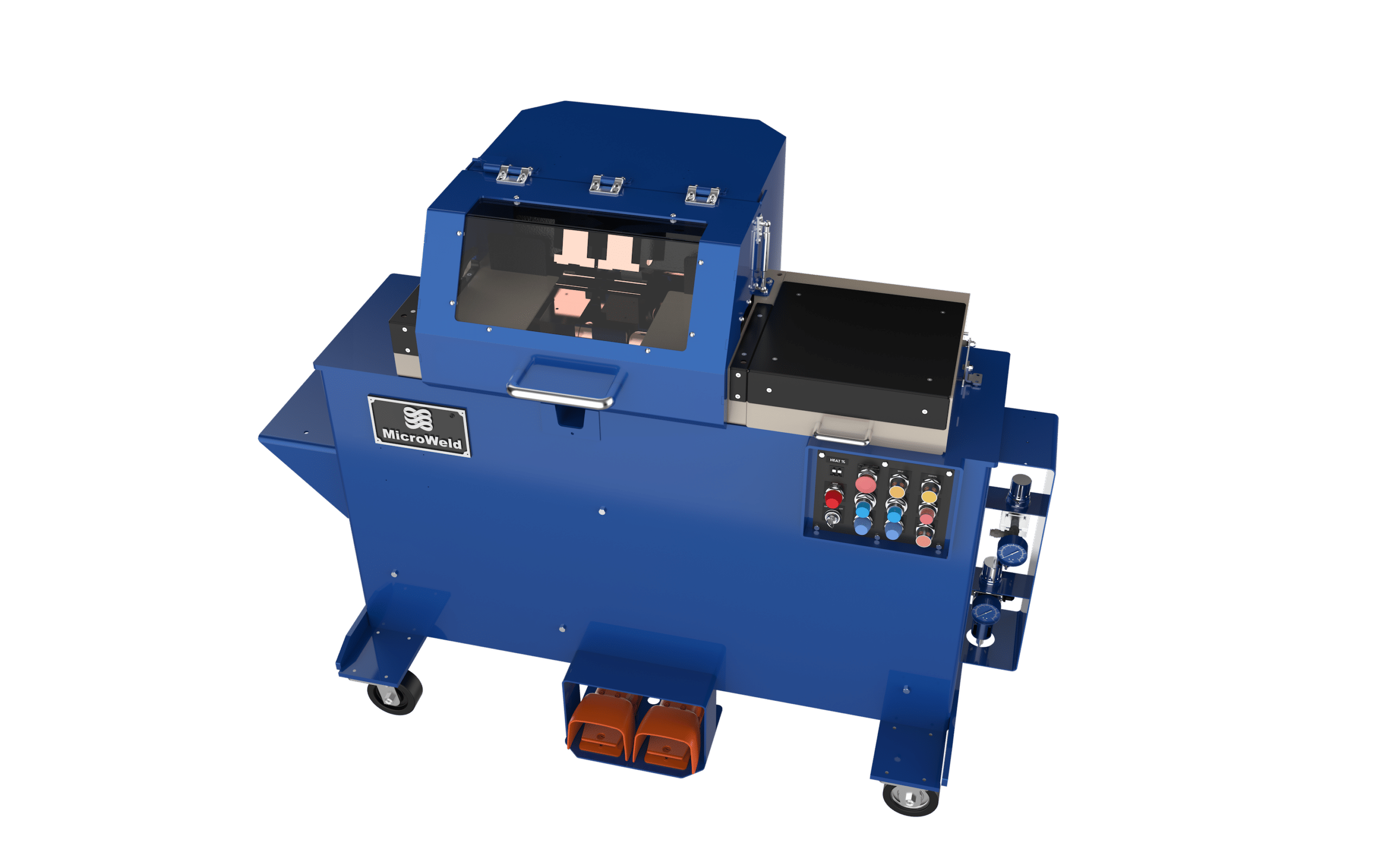

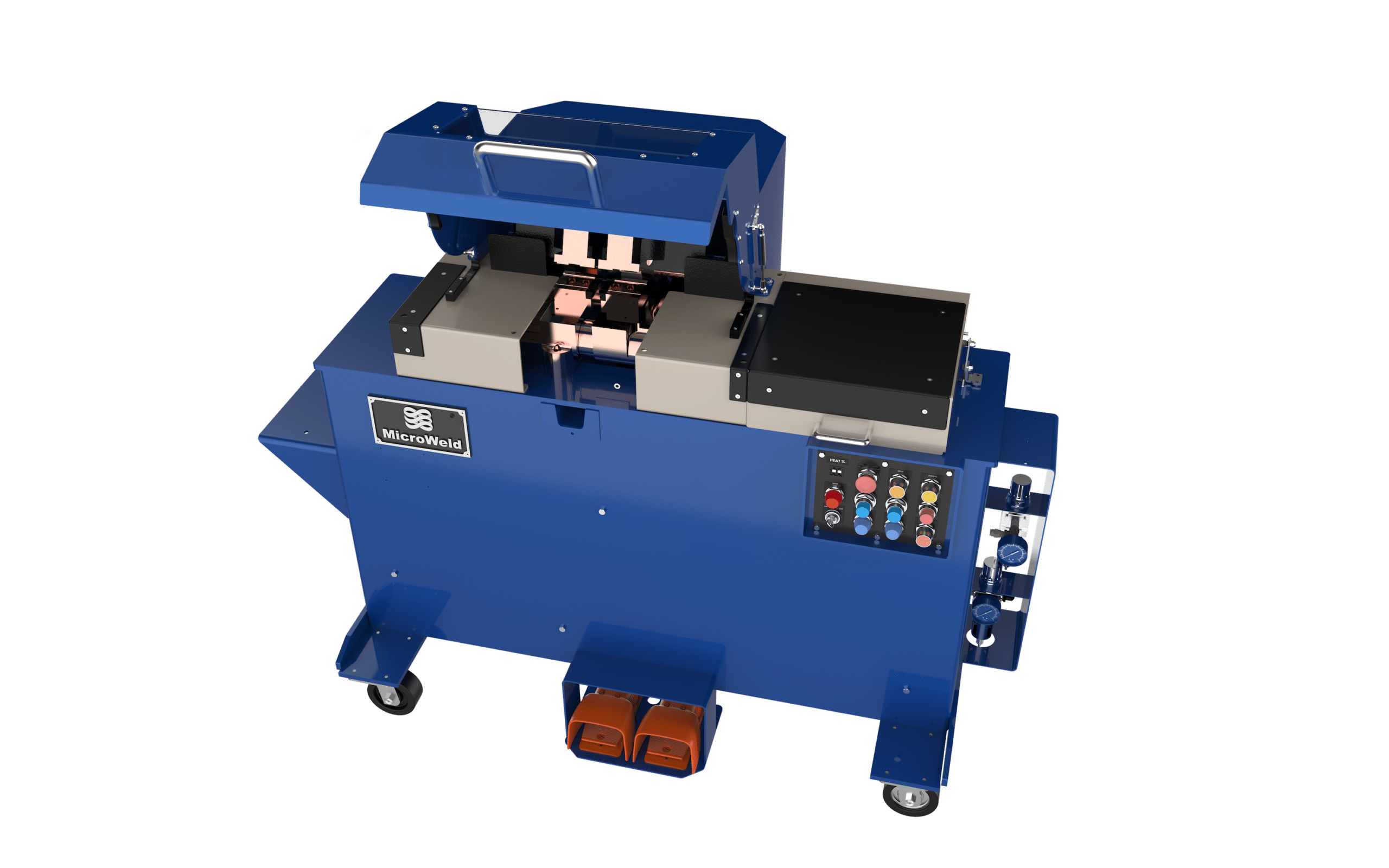

MD-6

Introducing Micro Weld’s line of MD model welders, designed specifically for efficient and high-volume welding of large-diameter steel rods. Our MD model welders produce consistently high-quality welds that are uniquely formed under heavy upset pressures delivered by a motor-driven cam assembly. Our extra heavy-duty transformer is the most stable and cost-efficient option available today to steel rod producers and processors.

For ease of use and precise positioning, our MD model welders also feature foot-controlled individual clamping pedals, allowing for easy placement and adjustment of material position. The heavy-duty clamping mechanism is pneumatically controlled to ensure positive positioning and is equipped with cylinders that have long-lasting neoprene diaphragms.

Standard Electrical Equipment:

- Weld Transformer Wound for 480 Or 600 Volt, 60 Cycle, Single Phase A/C.

- Equipped With A 6 Pt Heat Selection Switch

- 120 Volt Control Circuits

- Safety Flashguard Interlock Switch

- 1 1/2 Hp Ac Motor (SCR) Speed Control

- Push Button Operation

- Heavy Duty Stepdown Transformer.

Standard Mechanical Equipment:

- Complete With Pneumatically Operated Foot Controlled Clamping Mechanism

- Motor-Driven Cam Upset Mechanism

- Heavy Duty Straight

- Slide Movable Headpiece

- Flashguard

- Watercooled Headpiece

- Arm Type Anneal Mounted On A Heavy Duty Four Wheel Truck With Caster Wheels

Width Across the Front: 92 in (234 cm)

Depth to the Back: 38 in (97 cm)

Height: 63 in (160 cm)

Weight: 5770 lbs (2620 kg)

- Heavy Duty Screw Type Anneal Xcal

- Heavy Duty Vise